The whole process is handmade in every single steps:

- Model-making. An artist creates an original model from wax, clay, or another material.

- Mold making. A mold is made of the original model or sculpture. The rigid outer molds contain the softer inner mold, which is the exact negative of the original model. Inner molds are made of latex, polyurethane rubber or silicone, which is supported by the outer mold, which is made from plaster. This mold can be used to make multiple copies, limited only by the durability of the mold.

- Wax. Once the mold is finished, molten wax is poured into it and swished around until an even coating, usually about 3 mm thick, covers the inner surface of the mold. This is repeated until the desired thickness is reached. The mold is turned upside down and the wax layer is left to cool and harden. With this method it is difficult to control the overall thickness of the wax layer. This hollow wax copy of the original model is removed from the mold.

- Chasing. Each hollow wax copy is then "chased": a heated metal tool is used to rub out the marks that show the parting line where the pieces of the mold came together. The wax is dressed to hide any imperfections and the wax now looks like the finished piece.

- Spruing. The wax copy is sprued with a treelike structure of wax that will eventually provide paths for the molten casting material to flow and for air to escape. The carefully planned spruing begins at the top with a wax "cup".

- Investing. A sprued wax copy is covered in the plaster slurry and the process is repeated until at least a half-inch coating covers the entire piece. Only the cup is not covered. Wire is used to tighten the invested shell to prevent expansion during heating. The invested shell is then heated so that wax will burn off, leaving the cavity hollow, ready for the molten metal. The shell also has to be hot because otherwise the temperature difference would shatter it.

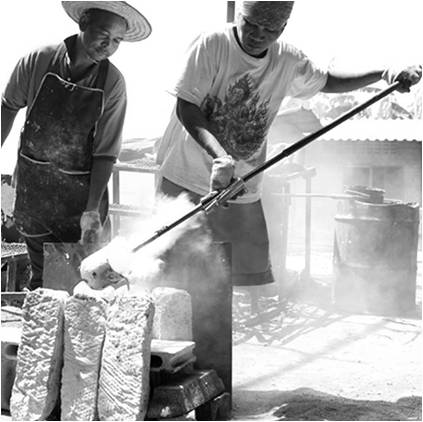

- Pouring. Metal is melted in a crucible in a furnace, then poured carefully into the shell via the cup. The filled shells are then allowed to cool.

- Release. The shell is hammered or sand-blasted away, releasing the rough casting. The sprues are cut off, the material to be reused in another casting.

- Metal-chasing. The casting is worked until the telltale signs of the casting process are removed, so that the casting now looks like the original model. Pits left by air bubbles in the casting and the stubs of the spruing are filed down and polished.